Description

Precision-Cut Corrosion-Resistant Nitinol Waveguide Tubes for Advanced Medical Devices

Welcome to the forefront of advanced medical manufacturing. We specialize in laser cutting Nitinol components, with a key focus on the Corrosion-Resistant Nitinol Waveguide Tube—a critical part in high-performance medical laser systems. Our precision services bring shape memory metal to life, powering the next generation of life-saving technologies.

What is Nitinol?

Nitinol is a unique alloy composed of approximately equal parts Nickel and Titanium. It belongs to a class of “smart metals,” offering remarkable flexibility, shape memory, and superelasticity. Nitinol bends further than traditional metals like stainless steel—without breaking—and always returns to its original shape when heated.

How Shape Memory Works

Nitinol’s shape memory effect is rooted in phase transformation. The alloy switches between two atomic structures—martensite (low temperature) and austenite (high temperature). At high temperatures, manufacturers “set” a shape. When cooled, the material can be deformed, only to return to its memorized shape once reheated. This behavior makes it ideal for medical applications that demand both flexibility and dimensional precision.

Why Choose Our Corrosion-Resistant Nitinol Waveguide Tube?

Our Nitinol waveguide tube plays a vital role in laser-based medical procedures. It’s engineered for durability, precision, and safety:

-

Enhanced Corrosion Durability – Resilient against biological fluids, salt-rich environments, and harsh sterilization processes.

-

Excellent Biocompatibility – Made from certified medical-grade Nitinol, safe for internal use.

-

Shape Memory & Flexibility – Navigates complex anatomy and returns to form.

-

High Precision – Laser cutting ensures micron-level tolerances, essential for efficient light transmission.

Advantages of Laser Cutting Nitinol

For medical-grade Nitinol shaping, laser cutting remains the preferred technique. Its primary advantages are:

-

Extreme Precision – Achieves tight tolerances for intricate features.

-

Burr-Free, Clean Edges – Reduces the need for additional processing.

-

Low Heat Impact – Preserves the shape memory and superelastic properties of Nitinol.

-

Non-Contact Method – Prevents tool wear and deformation.

-

Complex Geometry – Ideal for slots, holes, and fine structures used in implants and devices.

Key Medical Applications

Our laser-cut Nitinol components are used in a wide range of critical applications:

-

Minimally Invasive Surgical Tools (guidewires, catheters)

-

Cardiovascular Stents

-

Endoscopic Instruments

-

Cardiac Valve Frames & Occluders

-

Bone Fixation Devices

-

Precision Waveguide Tubes for laser-based diagnostics and treatment

FAQs – Laser-Cut Nitinol Tube

What makes your tube corrosion-resistant?

The native oxide layer on medical-grade Nitinol offers exceptional resistance. We preserve this layer through precise, contamination-free processing.

Can you cut ultra-thin walls?

Yes. Our advanced lasers enable clean, accurate cuts on delicate Nitinol hypotubes with no deformation.

What finish can I expect?

We provide smooth, clean cuts. Optional electropolishing ensures a mirror-like, biocompatible surface.

What tolerances can you meet?

We routinely meet sub-10-micron tolerances, depending on the application.

Do you offer different Nitinol grades?

Absolutely. We support both superelastic and shape memory grades based on your device’s functional needs.

Nickel Titanium vs Stainless Steel

While stainless steel is more rigid and economical, Nickel Titanium (Nitinol) offers:

-

Greater fatigue resistance

-

Higher corrosion resistance

-

Superior flexibility

-

Better strength-to-weight ratio

For dynamic, implanted, or flexible-use devices, Nitinol is the more durable and reliable choice.

Partner with Us for Precision Nitinol Manufacturing

Our team is dedicated to delivering high-precision Corrosion-Resistant Nitinol Waveguide Tubes and custom laser-cut Nitinol components. With a focus on biocompatibility, durability, and engineering precision, we empower the development of safer, smarter medical devices.

Contact us today to start your next project and explore the full potential of laser-cut Nitinol in medical innovation.

▸ Expert Guidance: 24/7 support

▸ Facebook account:Facebook

East Asia Region:nitinolwire.com

Europe Region:nitinolmetal.com

US Region:nitinolalloy.com

Mid East Region:getnitinol.com

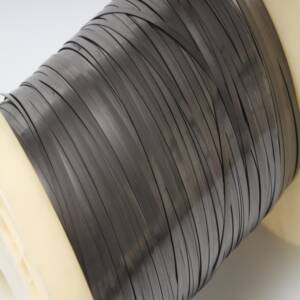

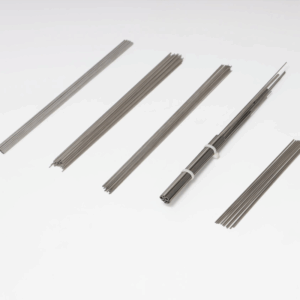

Nitinol Flat wire– Superelastic and shape-memory wire for medical, industrial, and smart device applications.

Nitinol Tube – Precision-engineered tubing ideal for minimally invasive devices and high-performance systems.

Reviews

There are no reviews yet.